2023_06_23 Two weeks ago, Al and I spent the day fixing up Trentham.

And this old fella could not have done it without Al's help or these special tools.

SPECIAL TOOLS (Not human kind ;)

This trolley helps me to work under the lower bench top. Its slightly lifted off the floor, to help with holding arms up and seeing the work being undertaken. Using magnifying glasses (3.00) makes it easier too.

This adjustable trolley was built by Graeme and uses a mechanics trolley. Removed the wheels and put them on the frame. Also works a treat. Except.... for last Thursday!

More to come later!!

Changing track down end of Trentham (old Shinohara three way point had power routing problems and constant derailments)

With a lot of work, Al got the Peco code 75 three way point installed with only one kink that I can see. He did great work as he usually does. However electrical gremlins meant we had to return here the following Thursday

Trains would run into the dock, however a direct short occurred when trying to run in or out of the platform road. Got to be a simple problem, eh?

Turns out an easy fix. The connector on the Tortoise (used at Trentham) Was incorrectly fitted and shorted out the feed to the frog.

AS it turned out, unfortunately, I used the high trolley to get under and fix the point. I could not see the Tortoise properly as it was behind framework. I slid forward and there lies the problem. After seeing the connector was shorting, I fixed that problem. Al tested a loco through the points and it was time for me to come out from under. When I sooted forward, I did not realise that the red tray had bent under my weight.

And then Al pulled the trolley out.... OUICH!

Two points and a section of track well and truly buggered!

Fortunately Al fixed one point.

And it was easy enough to replace the flexi track.

Work in progress.

Ok all done.

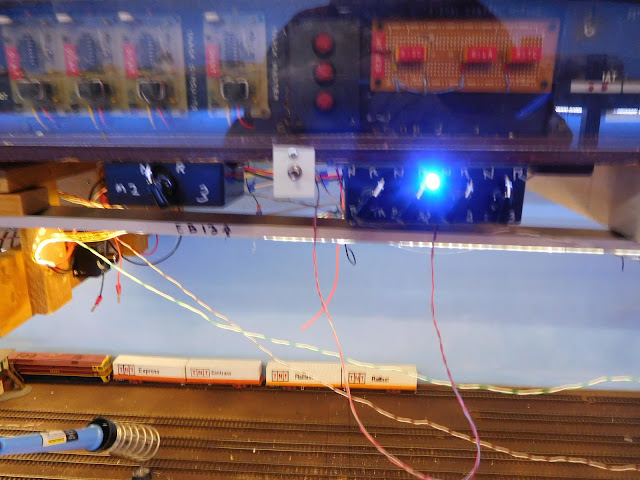

So next week we will wire in the last point motors (if I get a panel finished by then.

We have taken away the Tam Valley Octo switches (p/b with leds) and installed toggle switches (to match the simple switches) Their are 18 point motors required to power Wodonga yard. I have two more simple switch 8's to add to the Octo (8) switches in place.

And so this is the final bit. All point motors installed, just the toggles and panel to go.

Two simple switches are waiting to allow for 16 switches and servo point controllers.

Cheers Rod