And its Australia Day 2024

Time flashes by when you are having fun! (not)

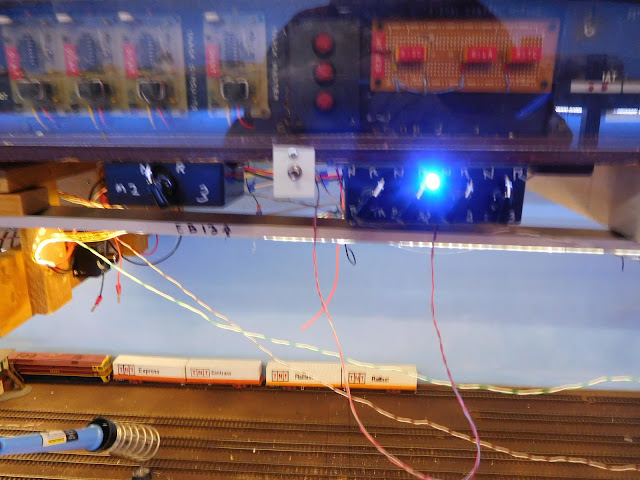

So our little team, has continued to plod on, although we really have little we can show you guys. The wiring project, has taken most of our time.

My stupid setup in the early days has caused much heart ache, however the light is now visible at the end of our tunnel.

I am now happy we used servo motor point motors, and paying $3.00 each instead of $50+ for the much better Tortoise motors is a real sweetener for one who has the need for near 150 points to change.

I was certainly not so convinced after suffering multiple failures with Tam Valley control switches (maybe a result of my crap wiring?) and changing to ANE (Peco) switches was not much better. However along came David and his Simple Switches (Click here to see them).

All I can say is Where were you 10 years ago? These things are brilliant!

So we replaced the faulty Tam Valley bits and all the ANE bits with Simple Switches and most of our problems went away.

Now every indication I got in the early days was Tower Pro SG90 were the best of the cheap servos and ideal for model railway use. I found this to be true and the first 50 installs operated flawlessly (they did not rattle and changed tracks easily when the Tams decided to work). However the next 25 were not so good. I believe they were cheapened, and I guess almost every one has failed. I was told to search for Tower pro SG90 with metal gears. I found them and bough another 25 and they are working very nicely. Another order for 25 will probably allow me to power my Heritage 2 POS signals.

So there you go! Six months of electrical, and time to run a few trains?

I can add a few pictures here to show other progress, if I can find them?

Progress Pictures

Here we have some bits Al sourced from his son Neil, cut on a CNC machine.

The first are replacement coupling pins between a LIMA 38 and its tender

You can contact me, and I will let Al know your phone number if you could use one of these?

The next are replacement drive shafts for a Trainorama S Class (GM and 42 Class)

We asked Neil to make some on his CNC machine. Thanks Neil.

Here are pictures of the shafts installed. I used to think that pulling the bogies apart to change split gears was near impossible. However completely pulling the chassis apart, still did not fix the problem. So I used the dremel to cut out slots to drop the motor back into place with the shaft already pushed in both ends of the motor.

They are a proper bastard to fit. Even worse than the damn bogies, when you try to replace cracked gears.

We had to use the dremel to get the shafts in. Fit them to the motor and push down as you line up the gear box. 4 Hands anybody?

OOPS! It was a run away :(

Its a huge layout, and difficult to know if you remembered to change those points. Anyway looked spectacular. You will notice that some locos are not on track (apart from crashed ones) We were still trying to find wiring problems.

Wiring? Well the new Control Box has a lot of spaghetti in it, I guess?

Scenery

Lastly, I cannot find the new scenery pictures I took over the last several months. I think they are lost. So next time Graeme comes over, I will do some update pictures then.

First thing is my Australia day 2024 Video

https://youtu.be/BCmvJ1w6dj0

And lets run an 90's pass on Australia day :D Please forgive the edit which failed to show the second person safely connecting up the cars and waving the train back into the dead end.

And so after running around and pushing back its time to head back to Melbourne

Sorry about the time warp. I took this video several times trying to make it right. However you will see my mistake, easily.

Cheers all

Hope you all had a Happy and Holy Christmas with your loved ones...

And a Happy New Year to you all.

Rod Young