He! He! He!

my points have arrived, and I ordered the underlay. Its time to lay some track. (also have about 40 m at hand to start with)

Going to build the first BG Station (Wangarroo) and run up through the helix up to the top level, along the long wall, around the back and into the new centre island, where it will connect to the old Trentham layout, which will be lifted into the upper level in a few days. Trentham will continue on and swing left along back wall to other side wall and enter a dead end terminus, which Tony K of McKenzie and HO lLand has taken possession of.

I was having a problem sorting out the branch, and now I am particularly happy with the way it has worked out.

Cheers

Rod

Continues

Who would like a Victorian Rail Motor from China?

Rumours are around that Auscision will announce a new project in about 6 months.

It is said to be a 280 Walker with blue roof. Not sure if it will have a trailer, but if you want one, e mail Auscision and encourage them to build the model. They have received the engineering drawings and are very happy with them.

However can they sell enough to make it worth their while?

I want 2

Cheers

Rod

ps eureka have caused some minor problems, reserving the 153 and 102 hp Walkers with the factory. The 280 has been accepted by China as a different model. However it will be silly for Eureka to go ahead after the 280 arrives. The 280 shares common parts with the smaller versions, as far as I know.

2009 September 23

The points arrived, but they were narrow gauge! We

sent them back, and when they rang me, I went down and found they were

large radius straights instead of curved

Still waiting.....

However I have started laying track around the first level of the helix, as well as the double track storage siding. Slight re-arrangement of the points at the station throat to accommodate the widest possible curve into the storage loop and helix, and just maybe we will have something to take a picture of, next Saturday.

Tony K is visiting, again, on Friday, so hopefully I will have about 30 m of operable track to test our A Class's out on. This underlay works really well too.

Have any of you guys used End of the Line Hobbies in Victor Harbour SA? What a nice bunch of people they are. Honest prices, kit building service, and good stocks of Peco, I highly recommend them to you, if you require mail order or particularly if you are local.

08 85527900 End of Line Hobbies

Cheers

Rod

Still waiting.....

However I have started laying track around the first level of the helix, as well as the double track storage siding. Slight re-arrangement of the points at the station throat to accommodate the widest possible curve into the storage loop and helix, and just maybe we will have something to take a picture of, next Saturday.

Tony K is visiting, again, on Friday, so hopefully I will have about 30 m of operable track to test our A Class's out on. This underlay works really well too.

Have any of you guys used End of the Line Hobbies in Victor Harbour SA? What a nice bunch of people they are. Honest prices, kit building service, and good stocks of Peco, I highly recommend them to you, if you require mail order or particularly if you are local.

08 85527900 End of Line Hobbies

Cheers

Rod

2009 September 24

So here I am sitting here 18 working hours into my track laying session and only two points and two lengths of track glued in

Well I guess its not all that bad, however it occurred to me as I was laying the first point, that I needed to drill a hole for the point motor. Good thinking! Then I thought, "Hold on, I have never laid track for DCC before, and is there anything I need to do different in DCC to DC?"

So I read the blurb Peco writes in the instructions, and found it did not help much!

So then I googled Peco and DCC, and found this site... Welcome to the website that coined the phrase "DCC Friendly!" Thank goodness I did.

So now I have to remove shunts and make new ones to sort out the Peco Electrofrogs and modify the few insulfrogs that I am going to use as well.

AS an example, this is what Alan says about Electrofrogs

Peco "Electrofrog" Turnout Is DCC Friendly In Just a Few Snips.

Code 75, 83, 100:

The Peco turnout is a clever design. It can be a typical power routed turnout or a DCC friendly one. It is proof positive that manufacturers can make turnouts that suit all modellers' needs without it costing more to make them.

Let this be a public thank you on behalf of all model railroaders for a company responding to the needs of those who buy your product - by choice and because modellers like it, not because it is the least evil on the market.

This is a great improvement. The problem with the frog shorting is completely eliminated with no serious cutting effort on the part of the modeller required. Not only does not modeller not need to saw on the turnout, potentially risking damage, but also the jumpers around the frog do not need to be cut.

The only jumpers that need to be cut are those shown. Be careful not to cut those across the frog!

You have less problem of a dead frog with this arrangement. Furthermore, the desire to use a light bulb is drastically reduced.

I am also told that powering the frog is now provided by some wires (in some form since I have not yet seen this turnout) that come out the side. It sounds like the old Atlas/Roco that was an excellent turnout.

Congratulations Peco!

How to Wire This Turnout:

This section assumes you have read "How to Wire Turnouts" in the section on turnouts.

1. Remove jumpers from back of frog as shown.

2. Add jumper between stock rails and closure rails as shown. Or, for less solder joints to your track, drop feeders from each closure rail to your buses as shown in color above.

3. Connect the frog to your power routing switch or switch machine.

4. Connect your power routing switch or switch machine to your bus as shown in the above drawing. If the locomotive shorts when it goes across the frog, swap the wires that connect your power routing switch or switch machine to your bus.

5. Install insulated joiners as shown.

6. Run a wire from each point rail to the corresponding bus wire as shown in color above.

7. Run a wire from each stock rail to the corresponding bus wire as shown in color above.

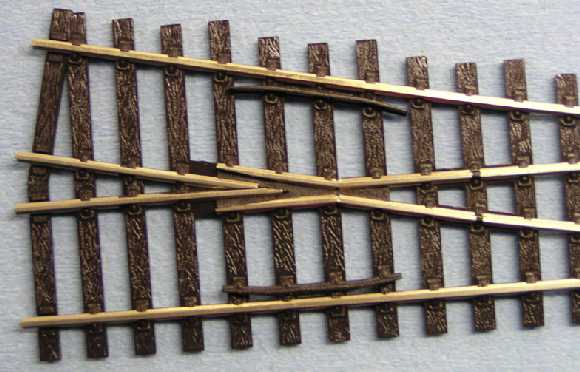

Electrofrog - Top View

Note the insulating gaps in the closure rails in the right half of the picture.

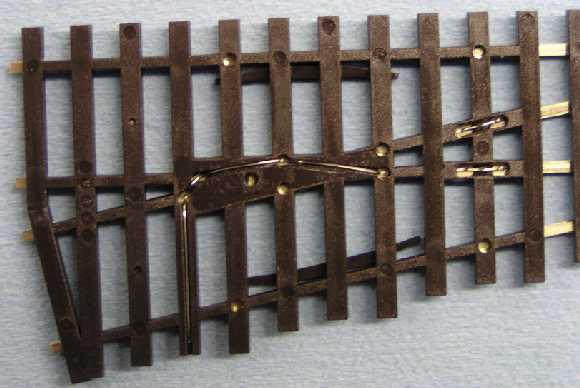

Electrofrog - Underneath View

Notice bonds between stock and closure rails in right side of view. Also, the jumpers have been cut. Also note the wire leaving the frog and dropping towards the bottom of the picture. Solder a wire to this to power route your frog.

And so I need do a little more than drill a hole for the actuator to move the blades

Cheers

Rod